3D printing & prototyping

3D printing components and small-batch 3D production in Austria

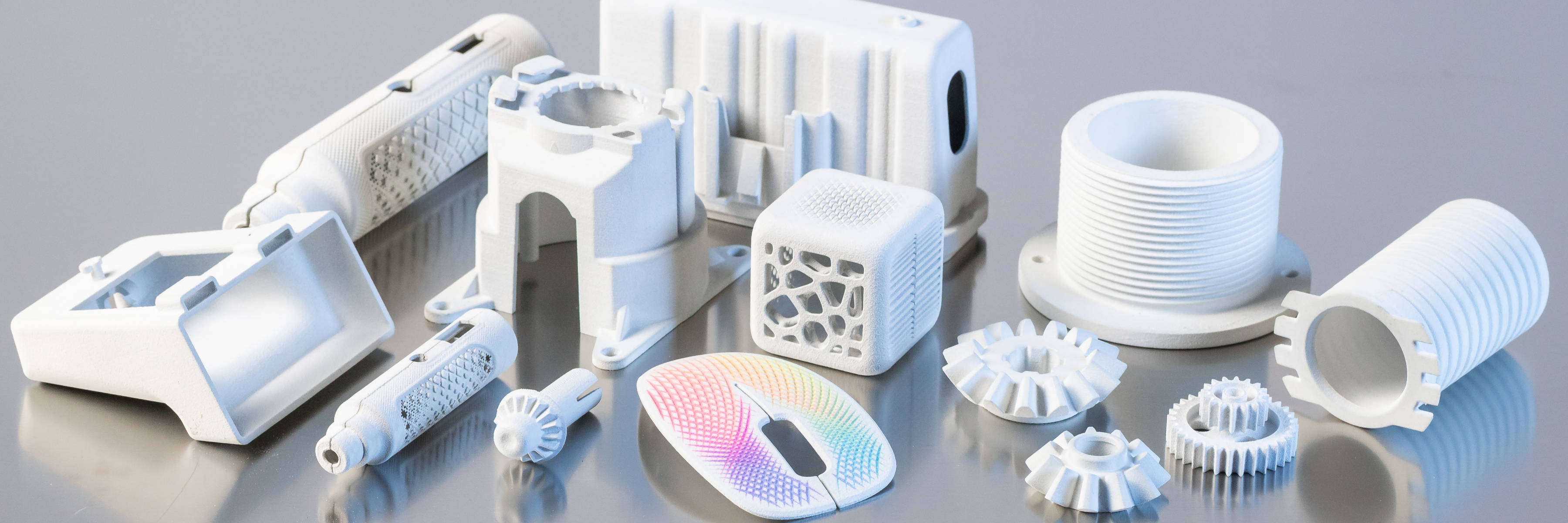

In addition to various injection moulding processes, we also offer 3D-printed components, small series and pad printing. 3D-printed components are particularly interesting for those who want to produce small series of 3D-printed parts and want to invest as little money as possible in the manufacture of a tool. The latter are an essential extension of our plastic manufacturing processes and enable the printing of complex surfaces and a wide range of materials.

What is 3D printing?

3D printing refers to the creation of a three-dimensional workpiece made of plastic (and sometimes other materials) based on a digital CAD template. Printing is usually done layer by layer, with the required raw materials added as liquids or powders and solidified in various melting and curing processes. Similar to various injection moulding processes, several components can also be combined in 3D printing. This results in 3D-printed components such as hard plastic parts with soft gripping surfaces, objects with individual components of different colours and properties, or those with parts that move relative to each other. 3D printers are used in a wide variety of fields, including automotive engineering, jewellery manufacturing, construction, aerospace and medical technology.

On the one hand, 3D printing can be used to produce finished plastic parts that are ready to print and ready for use. These are usually smaller plastic components. On the other hand, tools can also be produced that can in turn be used for the production of injection-moulded parts. In this case, particular attention must be paid to the high stability and temperature resistance of the moulds produced in the 3D printer. In addition, a combination of 3D printing and injection moulding can be produced, whereby the outer shape of a component is manufactured in the 3D printer and its inner cavity is filled with injection moulding to ensure the highest possible stability. These types of part printing are additive processes and offer various advantages.

3D printing prototypes

One of the biggest advantages of 3D printing is that it does not require tools to be manufactured in advance. The production of precise moulds, into which injection moulding is fed and in which it is cured, is often somewhat more cost-intensive due to the complexity involved. Nevertheless, this approach is still quite profitable, especially for large quantities per part series, thanks to broad cost distribution. However, if you want to have several small series produced, the economic efficiency of the project may suffer. In these cases, 3D printers are the optimal solution. Whether for printing an inexpensive tool as the basis for a less extensive series of parts or as an instrument for manufacturing the desired plastic components themselves: with our 3D printers, you can also cost-effectively produce 3D-printed components, test series, small series and prototypes.

One disadvantage may be the lower stability compared to a component manufactured using injection moulding. While 3D printing produces components from individual layers stacked on top of each other, injection moulding produces them in one piece, making them particularly stable. The decision between the two processes ultimately depends on the intended use and the economic efficiency that can ultimately be achieved. In addition, thanks to state-of-the-art technology, we are also able to produce particularly resistant technical components using the 3D printing process, for example by adding special hardeners or other materials with highly resistant properties.

3D printing of technical components and 3D printing of small series

We manufacture 3D-printed technical components and small series of 3D-printed parts for you on request. We also manufacture 3D-printed prototypes for you on request. The two most common types of 3D printing are stereolithography and laser sintering. We would like to briefly introduce both options to you. In stereolithography, a kind of lifting platform is located in a basin of epoxy resin. The desired model is created by piecemeal downward movements, between which the top layer of resin, approximately 0.05 to 0.25 millimetres thick, is cured. However, less complex shapes (e.g. due to protrusions and overhangs) are possible overall.

Laser sintering is based on two basins, each with a stage. One of the two basins contains plastic, metal or ceramic powder, which is picked up by a roller and rolled in a thin layer onto the adjacent lifting stage. A laser sinters (melts) this first layer, causing it to harden. The powder stage is then raised slightly, while the stage with the actual object sinks slightly. In this way, the actual component is created layer by layer. Thanks to the rapid hardening process, it is possible to create much more complex shapes.

HP Jet Fusion 540

3D printing using powder printing technology

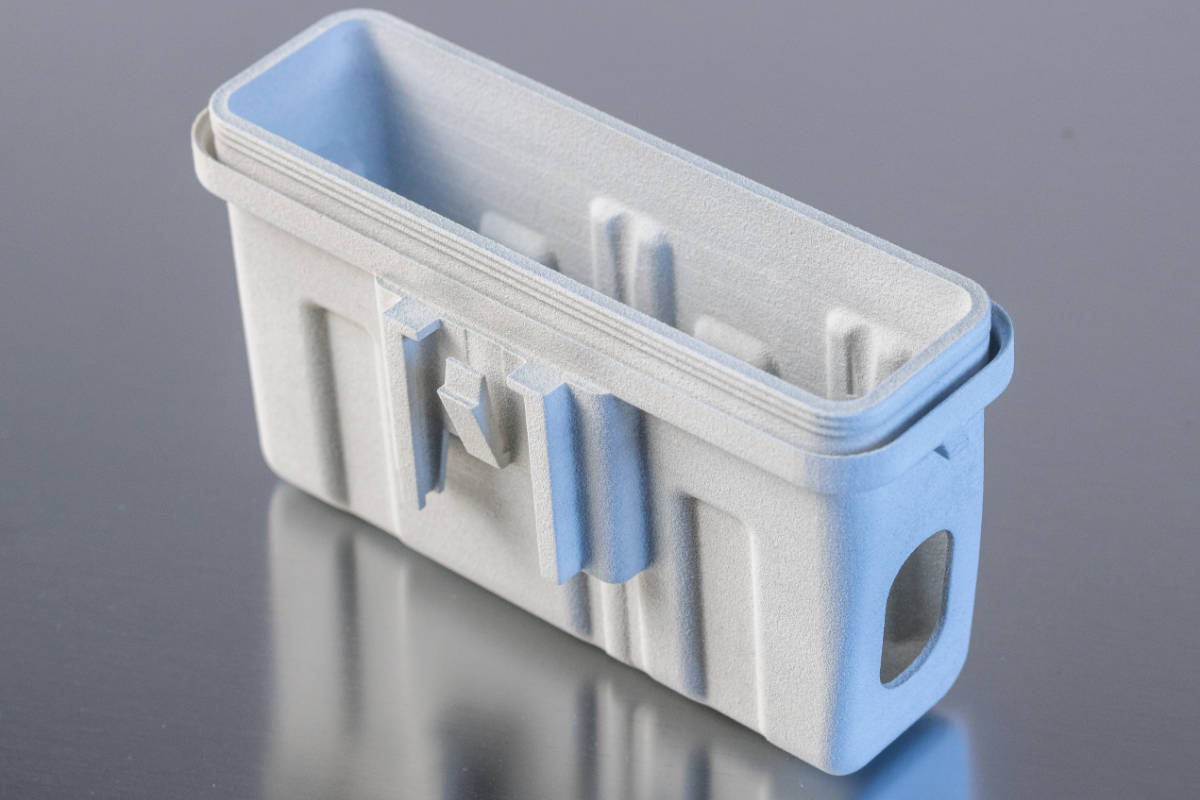

HP's state-of-the-art 3D printer uses the powder printing process. It uses a fine polyamide 12 powder, which is applied in layers of only 0.08 mm. Each individual layer is then immediately saturated with a so-called "fusing agent" and subsequently melted by an infrared lamp. The lamp is controlled in such a way that only the impregnated areas of material are heated, minimising the effect of heat on the components. This not only has advantages in terms of warping, but also shortens printing times. A "detailing agent" ensures that corners and edges are reproduced cleanly despite the melting process.

This results in a very homogeneous material structure with high density, which means that parts produced by this printer are even waterproof and can be used for tanks or containers, for example. Furthermore, the uniform structure ensures optimum mechanical behaviour under load. The strength of these parts is virtually independent of the direction of load. In addition, the strength can be controlled very well via the wall thicknesses. This makes it possible to print components that are both very rigid and flexible and elastic.

Due to the technology used, there is virtually no geometry that cannot be manufactured. Support structures or similar are not required here, which not only makes reworking more efficient, but also results in better surface quality.

Compared to other prototyping processes that also use powder, such as SLS (selective laser sintering), HP's technology offers the advantage that not only is the density and homogeneity of the printed parts higher, but also, due to the lower heat input, there is less warping and shorter build times.

Often, only a small number of individual components are required for a project, which means that the cost of an injection moulding tool has a significant impact on the unit price. With the new HP 3D printer, we now have the option of offering you a small series of printed parts directly, depending on the application. With over 35 years of experience in injection moulding, Hiebler has considerable expertise in project planning and the associated costs of small series production. Depending on the size and complexity of the component, you will see that it can be well worth printing a few thousand pieces before investing in an injection moulding tool.

This 3D printer is therefore not only suitable for individual prototypes and the simultaneous production of individual assemblies from a wide variety of parts, but also for small series, which can be manufactured quickly and cost-effectively.

Key data:

- Material: PA12

- Standard color: Light gray

- Paintable: Yes

- Installation space size: 332x190x248mm

- Print layer thickness: 0.08mm

- Accuracy: approx. 0.3%, lower limit 0.3mm

Our staff are of course available to answer any questions you may have and provide additional information. Simply contact us and be amazed at what this technology can do!

Maximum part size

| Normal resolution | 284 mm x 380 mm x 380 mm |

| Film thickness | 80 Mikron |

| Minimum feature size | 0,5 mm |

| Toleranzen | With good part design, tolerances of 0.25 mm (Ultrasint™ TPU-01: #0.30 mm) and +0.002 mm/mm can usually be maintained. Tolerances may vary depending on part geometry. |